The spring 2024 issue of Rice Engineering Magazine is here!

At Rice Engineering, we are driven by a passion for innovation and a commitment to responsible engineering practices. It’s with great excitement that we unveil the new design of Rice Engineering magazine, which underscores our dedication to excellence in research, education, and service. The 2023-24 issue is full of news about how Rice Engineering is solving for greater good.

Rice and MD Anderson advance cancer-focused operations research

Reginald Desroches, Rice President

Rice University and The University of Texas MD Anderson Cancer Center today announced the launch of the Center for Operations Research in Cancer, a joint initiative to solve complex challenges in cancer care using data science to make better operational decisions.

Integrating operations research into health care systematically and at scale can help reduce costs, improve patient experience and efficiently integrate cutting-edge technologies. Leveraging the expertise within Rice’s computational applied mathematics, operations research and statistics and MD Anderson’s Institute for Data Science in Oncology (IDSO), the new center will harness mathematical modeling and data science to optimize treatment delivery, improve therapy outcomes and streamline operations at the nation’s leading cancer center and beyond.

“We are constantly pushing the boundaries of what is possible in cancer care to advance our mission to end cancer,” said David Jaffray, director of IDSO and chief technology and digital officer at MD Anderson. “It is clear that operations research approaches can increase our capacity to care for patients, and the launch of this center is a major step in realizing that future.”

Dr. Caroline Chung, IDSO’s director of data science development and implementation and chief and data and analytics officer at MD Anderson, expanded on the importance of this collaboration.

“New methods and technologies are only capable of driving impact by carefully integrating these discoveries into operations in a way that maximizes the benefit and minimizes burdens,” Chung said. “This new effort with Rice in operations research will focus on that drive to impact for our patients and our mission.”

The confluence of technological advancements and an ever-growing demand for high-quality, cost-effective health care makes the collaboration timely.

“Rice has a critical mass of expertise in data science, and this collaboration is the perfect test bed for us to show what operations research can do broadly in health care, and specifically in cancer care,” said Amy Dittmar, the Howard R. Hughes Provost and executive vice president for Academic Affairs. “The goal is to enhance the efficiency of care while focusing on reducing the burden on patients and their families, making their experience more seamless and compassionate.”

Jeffrey Siewerdsen, professor of imaging physics and co-lead for the safety, quality and access focus area of IDSO, worked closely with Rice’s Andrew Schaefer, Noah Harding Chair and professor of computational applied mathematics and operations research, to create the center. They will serve as co-leads for the initiative.

“New technologies and therapies have driven major changes in cancer care compared to a decade ago, posing new challenges to clinical operations,” Siewerdsen said. “While operations research has transformed industries like transportation, manufacturing and logistics, its potential in health care is yet to be fully realized. New computational capabilities and high-quality data present a major opportunity to improve safety, quality and access to cancer care.”

In addition to the co-leads, center activities will rely on a steering group from each institution to help guide strategy, plan activities and measure outcomes. The joint center will serve as a hub, supporting collaborative research projects, pilot project seed funding and exchange of trainees, fellows and interns across various levels of undergraduate, graduate and postgraduate education.

“The problems we face in health care are more complex than those in other industries because they involve an explosion of possibilities unfolding under uncertainty,” said Schaefer, “It’s humbling that even if we can’t solve all these problems fully, our models can provide real insights and make meaningful differences in patient care.”

The center will tackle several areas of application with significant potential for impact, including:

● Forecasting and scheduling for improved patient experience, health care workforce satisfaction and optimal equipment and facilities management

● Managing complex treatment regimens that evaluate an exponentially large number of options and incorporate patient response

● Improving protocols for adaptive randomized clinical trials

● Cutting-edge modeling of tumor progression using genomics and other biomarkers

● Developing customized, patient-centric screening protocols to counter potential gaps in care due to large-scale, population-based models

● Developing evidence-based models for rare cancers

The Center for Operations Research in Cancer follows the launch of the Cancer Bioengineering Collaborative by Rice and MD Anderson this summer, which aims to develop innovative technologies and bioengineering approaches to improve cancer research, diagnosis and treatment.

Center for Membrane Excellence advances separation technologies for energy and sustainability

Rice University has established the Rice Center for Membrane Excellence (RiCeME), which is dedicated to developing advanced membrane materials and separation technologies for energy, environmental sustainability and chemical processing applications. The announcement was made during the Rice Global Paris Center Symposium held March 17-18 in Paris.

RiCeME aligns with the strategic priorities of Rice’s School of Engineering and Computing, focusing on energy and sustainability. The center aims to secure funding from federal agencies, industry partners and global collaborators to accelerate developing and deploying more efficient and sustainable membrane separation processes.

“Houston is the ideal place to drive innovation in membrane separation technologies,” said Menachem Elimelech, the Nancy and Clint Carlson Professor in Civil and Environmental Engineering and Chemical and Biomolecular Engineering, who will lead RiCeME. “Membranes are critical for energy-related separations such as fuel cells, carbon capture and water purification. Our work will enhance efficiency and sustainability in these key sectors.”

Mission and objectives

RiCeME’s mission includes advancing next-generation membrane materials.

Membranes act as selective barriers, allowing specific molecules to pass through while blocking others and are essential for separating reactants and products in energy conversion processes like fuel cells and electrolyzers.

“Membrane technology is transforming how we approach environmental challenges,” said Pedro Alvarez, the George R. Brown Professor of Civil and Environmental Engineering and director of the Rice WaTER Institute. “Improving selective separations, efficiency and scalability can drive solutions for clean water and sustainable energy.”

Collaborative Approach

RiCeME fosters a vibrant, interdisciplinary research environment by engaging faculty expertise from the departments of civil and environmental engineering, chemical and biomolecular engineering, materials science and nanoengineering and chemistry. This collaborative approach enables comprehensive investigation, from fundamental materials science to applied engineering solutions.

“Rice University is committed to pushing the boundaries of research that has real-world impact,” said Luay Nakhleh, the William and Stephanie Sick Dean of the George R. Brown School of Engineering and Computing. “RiCeME is a testament to our dedication to solving pressing global challenges through engineering innovation.”

The center prioritizes strong partnerships with Houston-area industries, including those in the oil and gas, chemical and energy sectors, addressing their specific needs such as water reuse and resource recovery. RiCeME’s research spans the entire development pipeline, encompassing membrane material design and synthesis, bench-scale testing and pilot-scale demonstrations.

“Breakthroughs in membrane technology will play a crucial role in addressing energy and sustainability challenges,” said Ramamoorthy Ramesh, executive vice president for research at Rice. “RiCeME’s interdisciplinary approach ensures that our discoveries move from the lab to real-world applications, driving innovation at the intersection of science and industry.”

Along with its research and deployment goals, the center also serves as a hub for knowledge dissemination and workforce development by hosting workshops, symposia and training programs on cutting-edge membrane science and technology.

Bioengineers awarded $3.4M for project to end polio

Rice University bioengineer Kevin McHugh has been awarded $3.4 million from the Bill & Melinda Gates Foundation for a project to incorporate protection against poliomyelitis (polio) into the combination vaccine that protects against five common and dangerous childhood diseases.

The research could help the polio eradication effort and play an instrumental role in improving access to immunization in low-resource settings ⎯ an important part of meeting sustainable development goals and achieving equity in health outcomes across the globe. Polio is a highly infectious disease that largely affects children under 5 and can cause paralysis, breathing difficulties and even death.

“Combining vaccines is a proven method for reducing the logistical burden associated with vaccination, which improves health care accessibility and vaccination rates, especially in low-resource settings,” said McHugh, assistant professor of bioengineering and chemistry and a Cancer Prevention and Research Institute Scholar. “Unfortunately, in some cases the components present in one vaccine formulation can render another vaccine less effective, limiting the ability to combine those vaccines in a single vial.”

Building on the recent development of polioviruslike particles (VLPs) that mimic the outer shell of the virus but carry none of the viral genetic material, the McHugh lab at Rice aims to use its fabrication platform called PULSED (short for Particles Uniformly Liquified and Sealed to Encapsulate Drugs) to mitigate the risk of incompatibility between polio VLPs and materials present in the pentavalent vaccine.

“Encapsulating polio VLPs in our PULSED microparticles allows us to form a barrier that physically separates polio VLPs from the incompatible components of the pentavalent vaccine,” McHugh said. “Then once the body has naturally cleared these components from the injection site — an interval we posit could be two to four days — polio VLPs will be spontaneously released from PULSED microparticles, which will allow the recipient to attain the full benefit of all the vaccines administered.”

Incorporating polio VLPs into the pentavalent vaccine formulation would make it octavalent, i.e. capable of protecting children under 5 from eight different pathogens ⎯ diphtheria, tetanus, whooping cough, hepatitis B, a type of bacteria that can give rise to pneumonia and meningitis and all three strains of poliovirus.

Vaccines teach the immune system to recognize and attack pathogens before they spread and infect the host organism. One of the mechanisms for achieving this is to present the organism with something that looks like the virus but will not cause illness ⎯ often this consists of viruses that have been chemically treated to eliminate their infectivity while retaining their structural similarity to the live virus. This is the case of the inactivated poliovirus vaccine, which requires growing live poliovirus in a cell culture and then chemically killing and purifying the virus from the cells. In contrast, VLPs remove the requirement for poliovirus production, therefore eliminating the risk of accidental exposure during manufacturing.

“Our hope is to make a polio-free world a reality,” McHugh said.

Thanks to the Global Polio Eradication Initiative, the number of polio cases worldwide has dropped by over 99% since 1988, but the disease has persisted in areas with poor access to immunization and threatens resurgence, especially in areas with compromised infrastructure such as conflict zones. Most recently, the disease made headlines for an outbreak in Gaza.

“We are honored by the foundation’s support and eager to put our plan into action,” McHugh said.

Researchers innovate smarter wearable tech

In the world of soft robotics and wearable technology, sheet-based fluidic devices are revolutionizing how lightweight, flexible and multifunctional systems are designed. But with innovation comes challenges, particularly in understanding and controlling failure in these devices. A new study by mechanical engineers at Rice University’s George R. Brown School of Engineering and Computing explores how programmed failure in heat-sealable, sheet-based systems can be used to protect devices, enable complex sequencing of actions and even streamline control mechanisms.

“Put simply, we are making soft, flexible machines smarter by designing their internal components to fail intentionally in a well-understood manner,” said Daniel J. Preston, corresponding author and assistant professor of mechanical engineering. “In doing so, the resulting systems can recover from pressure surges and even complete multiple tasks using a single control input.”

The research, published in Cell Reports Physical Science, focuses on how thin, flexible sheets — patterned and selectively bonded to form internal fluidic networks — respond to pressure changes and, specifically, how they fail when internal pressures get too high. By studying adhesion between textile sheets, the research team was able to predict maximum operating pressures and determine how factors like bond geometry and material selection impact performance.

“Our study provides a framework for predicting and leveraging failure in sheet-based fluidic systems,” said Sofia Urbina, co-first author of the study, second-year doctoral student in Preston’s lab and a GEM Associate Fellow. “Rather than seeing failure as a limitation, we explored how it can be used to enhance functionality, making these devices more intelligent and efficient.”

Through rigorous testing, including T-peel tests to evaluate adhesion strength and burst tests to assess failure at elevated pressures, the researchers identified three distinct failure regimes dictated by the thermal bonding step of the manufacturing process: an initial phase where bond strength increases with bonding temperature, a plateau where material strength dictates cohesive failure and a third phase where overheating during fabrication degrades material integrity.

These findings allowed the researchers to engineer a novel “fluidic fuse” — a protective component that relies on multiple bonds with different strengths and is designed to fail in a controlled manner to prevent damage from pressure spikes. This component, the researchers said, was one of the most exciting outcomes of the study.

“Think of it like an electrical fuse,” said Preston. “When the pressure exceeds a set limit, the fuse ‘blows,’ preventing catastrophic damage to the entire system. This fluidic fuse can be easily replaced or even rebonded for reuse.”

Beyond protection, the team demonstrated that these fuses could be strategically placed to sequence multiple actions within a device. For example, in one experiment a system was designed to first unscrew a light bulb then lift it out of a socket — all using a single pressure input.

Beyond protection, the team demonstrated that these fuses could be strategically placed to sequence multiple actions within a device. For example, in one experiment a system was designed to first unscrew a light bulb then lift it out of a socket — all using a single pressure input.

“By programming when and where failure occurs, we can create devices that ‘fail’ their way into new operating modes, performing multiple tasks without needing additional control inputs,” Preston said.

The applications for these findings extend far beyond the lab. In wearable technology, fluidic networks could be embedded into clothing, offering adaptive support for rehabilitation patients, assisting individuals with mobility impairments and even communicating with our sense of touch. In robotics, the ability to sequence actions with a single input could simplify the design of multifunctional autonomous systems, reducing the need for complex electronic control mechanisms.

“This research allows for smarter, more responsive sheet-based fluidic devices,” said co-first author Adam Broshkevitch, who graduated from Rice with a Master of Science in mechanical engineering last spring and is now in the Air Force. “By embracing failure as a tool rather than a drawback, we can build systems that are not only more resilient but also more capable.”

Engineering senior to intern at SpaceX through Brooke Owens Fellowship

Rice University senior Cat-Linh Tran has been selected as a 2025 Brooke Owens Fellow, a prestigious honor recognizing exceptional undergraduates pursuing careers in aerospace. Tran, a mechanical engineering major, will spend the summer interning at SpaceX in Hawthorne, California, as part of the highly competitive fellowship program.

“I’ve been following SpaceX since high school, so the idea of working there as a Brooke Owens Fellow is a dream come true,” Tran said.

The Brooke Owens Fellowship, founded in 2016, is a nationally acclaimed nonprofit program that provides space and aviation internships, executive mentorship and a lifelong professional network. The program honors the legacy of D. Brooke Owens, an aerospace pioneer and pilot who passed away from cancer at age 35. Each year, a select cohort of “Brookies” is chosen through a rigorous application process that includes technical and creative submissions, leadership interviews and reviews by industry professionals.

The 2025 cohort was selected from more than 400 applicants across Ivy League institutions, major research universities, historically Black colleges and universities, liberal arts colleges, community colleges and international universities. Fellows are chosen for their technical talent, leadership experience, creative problem-solving skills and commitment to community engagement.

“Fellowships like this are so important because they provide access to mentorship, internships and a community of people who uplift and support each other,” Tran said.

Tran credits the Rice Emerging Scholars Program (RESP) — a residential initiative preparing first-year students for Rice’s rigorous STEM curricula — as pivotal in her academic journey and ultimately helping her earn such a prestigious fellowship. Inspired by her experience, she returned to RESP as a teaching fellow and said she is grateful to her adviser’s support throughout her time at Rice.

Tran’s engineering journey has spanned multiple fields, from biomedical design to heavy machinery. She has worked on a wearable grip assistance device, developed an enrichment feeder for the black bear exhibit at the Houston Zoo and interned at Wabtec (formerly GE Transportation) as a quality technical adviser for electric-drive mining vehicles.

She’s now taking her passion for engineering to aerospace, a field that first caught her attention during the COVID-19 pandemic when she was a senior in high school.

“I remember sitting at home, watching SpaceX launches on TV during quarantine,” Tran said. “It was fascinating, and it got me thinking about the future of space exploration.”

That spark turned into a full-circle moment in 2023, when she attended the Society of Women Engineers conference and toured SpaceX in person. During that visit, she met an engineer who was a past Brooke Owens Fellow, which is how she first learned about the program.

“It’s one thing seeing it on TV, but to see it in person is different,” Tran said. “At a time when I was doubting my career, the experience reignited my motivation for engineering and aerospace.”

With her focus firmly on aerospace, Tran is currently working with her senior capstone team to design an innovative rescue device for incapacitated crew members of extravehicular activities for NASA’s future Artemis missions — work she’ll almost certainly take with her after graduation.

Each Brooke Owens Fellow is paired with both an executive-level industry mentor and a “Brookie” alumni mentor to help guide them through their careers. In addition to working at SpaceX this summer, Tran will also attend the annual Brooke Owens Summit, where she will meet the rest of her 2025 cohort and aerospace leaders from across the industry.

“I can’t wait to meet my mentor and the other ‘Brookies,’” Tran said. “I’m super excited to join another supportive and inspiring community, and I hope to use this fellowship to uplift other women pursuing careers in aerospace.”

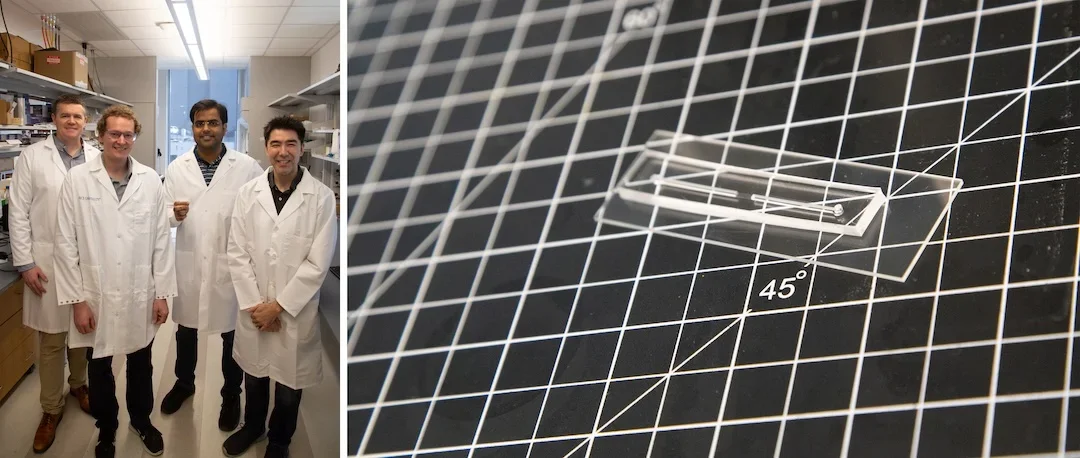

Gravity used to create low-cost device for rapid cell analysis

A team of researchers at the George R. Brown School of Engineering and Computing at Rice University has developed an innovative artificial intelligence (AI)-enabled, low-cost device that will make flow cytometry ⎯ a technique used to analyze cells or particles in a fluid using a laser beam ⎯ affordable and accessible.

The prototype identifies and counts cells from unpurified blood samples with similar accuracy as the more expensive and bulky conventional flow cytometers, provides results within minutes and is significantly cheaper and compact, making it highly attractive for point-of-care clinical applications, particularly in low-resource and rural areas.

Peter Lillehoj, the Shankle Chair in Mechanical Engineering and associate professor of mechanical engineering and bioengineering, and Kevin McHugh, assistant professor of bioengineering and chemistry, led the development of this new device. The study was published in Microsystems and Nanoengineering.

First developed in the 1950s, flow cytometry is a powerful technique for sorting and analyzing single cells that has applications in multiple medical fields including immunology, molecular and cancer biology and virology. It is the “gold standard” lab test for clinical diagnosis and care and is used extensively in biomedical research. However, its use is currently limited to state-of-the-art diagnostic labs and medical centers since it requires large, expensive equipment ranging from tens to hundreds of thousands of dollars and specially trained staff to operate it.

“Conventional flow cytometry is not practical for many resource-limited settings in the U.S. and around the globe,” said Lillehoj, the study’s corresponding author. “With our approach, this technique can be performed with ease for a fraction of the cost. We envision our innovative device will pave the way for many new point-of-care clinical and biomedical research applications.”

Leveraging gravity-based slug flow to build a low-cost, pump-free flow cytometer

Current flow cytometers rely on specialized pumps and valves for fluid flow and control, making the equipment expensive and bulky. After experimenting with several alternate microfluidic flow options, the Rice team devised an innovative pump-free design solution, which was key to reducing the device’s cost and size.

Desh Deepak Dixit and Tyler Graf — graduate students mentored by Lillehoj and McHugh respectively — fine-tuned various parameters of the microfluidic device to achieve gravity-driven slug flow. Unlike hydrostatic gravity flow where the fluid velocity changes depending on the hydrostatic pressure acting on the fluid, gravity-driven slug flow allows the sample to flow at a constant velocity through the microfluidic device, which is crucial for accurate cell sorting and analysis.

Slug flow is a two-phase flow pattern observed when a fluid composed of one or two fluids in discrete phases moves through a pipe or channel. It is used primarily for transporting large volumes of liquids through industrial equipment in oil and gas wells, chemical reactors and fermenters and is studied by researchers interested in fluid dynamics. “To our knowledge, this is the first time gravity-driven slug flow has been employed for a biomedical application,” said Lillehoj.

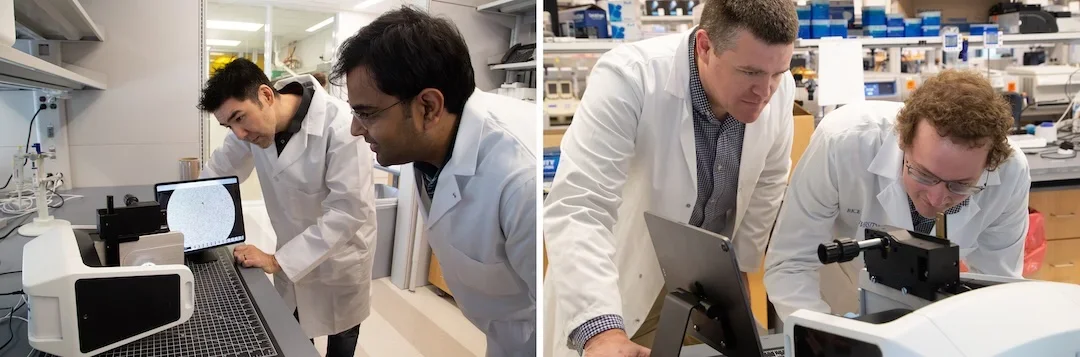

AI enables rapid counting of specific immune cells from unpurified blood samples

The study’s second important innovation was the use of AI, which facilitated rapid yet accurate counting of a specialized group of immune cells called CD4+ T cells from unpurified blood samples.

CD4+ T cell count is a reliable marker of the body’s immune status and is used as a diagnostic and prognostic marker for cancers and infectious diseases such as HIV/AIDS and COVID-19.

The team incubated unpurified whole blood samples with beads coated with anti-CD4+ antibodies, which allowed them to bind specifically to CD4+ T cells in the sample. The sample was then passed through the microfluidic chip, and the flow was recorded with an optical microscope and video camera. To speed up image analysis and quantification, the researchers added AI capabilities by training a convoluted neural network — a type of machine learning algorithm used for image classification and object recognition — to only detect cells labeled with beads.

“Identifying and quantifying CD4+ T cells from unpurified blood samples is just one example of what one can achieve with this platform technology,” said McHugh, who is also a Cancer Prevention and Research Institute of Texas Scholar. “This technology can be easily adapted to sort and analyze a variety of cell types from various biological samples by using beads labeled with different antibodies. Based on the promising results we’ve obtained so far, we are very optimistic about this platform’s potential to transform disease diagnosis, prognosis and the biomedical research landscape in the future.”

The research was supported in part by the National Institutes of Health (R21CA283852) and Rice (U50807). The content herein is solely the responsibility of the authors and does not necessarily represent the official views of the funders.