Jason Adams, assistant professor in the Department of Chemical and Biomolecular Engineering at Rice University, is at the forefront of a transformative effort to decarbonize one of the world’s most energy-intensive sectors: chemical manufacturing. By merging the fields of thermal and electrocatalysis, Adams is pioneering new ways to produce value-added industrial chemical products, including plastics, using renewable electricity instead of fossil fuels.

His goal: to fundamentally reimagine how chemicals are made, replacing high-temperature, fossil fuel-driven reactions with low-temperature, electrified processes that minimize emissions.

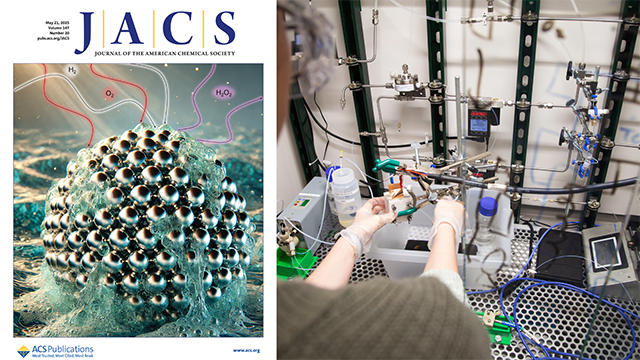

Adams’s lab is pursuing this mission with both creativity and scientific rigor. They build custom, fully automated flow reactors that enable high-throughput experimentation and precise control over reaction conditions. These systems will allow his team to vary catalyst compositions and test them using a broad range of thermodynamic conditions, generating physics-informed data sets to guide machine learning models for catalyst discovery.

“It’s not just about throwing data into black-box AI,” Adams said. “We want to embed physical insight into how we understand and design new catalysts. That’s how we identify materials that are both highly active and made from earth-abundant elements.”

In one of the lab’s recent breakthroughs, published in the Journal of the American Chemical Society, Adams and collaborators reported a novel approach to making hydrogen peroxide (H₂O₂)—a vital chemical used in everything from paper bleaching to environmental remediation—more selectively and sustainably. Their modified catalysts achieved up to 85% H₂O₂ selectivity in pure water and maintained performance for over 130 hours, without the need for harmful solvents or complex separation systems.

Beyond hydrogen peroxide, Adams’s lab is also working to electrify the production and recycling of olefins like ethylene and propylene, which are the basis for producing plastic products such as food packaging. Conventionally made through steam cracking at over 800°C, these chemicals alone account for about 1% of global CO₂ emissions. Adams’s group is exploring ways to generate them at room temperature using electrochemical oxidation of light alkanes, which could produce electricity as a byproduct—a radical departure from traditional approaches.

“If you have plastic anywhere around you, that likely came from an olefin. So what we’re working on would allow you to get to that product without having to go up to 800 Celsius. Instead, we are trying to make it at room temperature. I see it as a bridge technology that could convert natural gas to olefins, but could also use bio- or plastic-derived feedstocks to produce these nexus precursors in the future. If we made a really good material and process, thermodynamically, you could actually generate electricity and make olefins in a way that doesn’t emit CO₂.”

Ultimately, these efforts could enable the electrification of plastic upcycling: converting waste plastics back into their original chemical building blocks. “If we can make olefins from waste plastics, we’re completing a circular carbon economy,” he explained.

Adams’s research directly supports the mission of the Rice Engineering Initiative for Energy Transition and Sustainability (REINVENTS), bridging academic innovation with real-world industrial needs. “You could drop in this technology and produce the same critical chemicals, but in a cleaner and more efficient way, especially if powered by renewable energy,” he said.

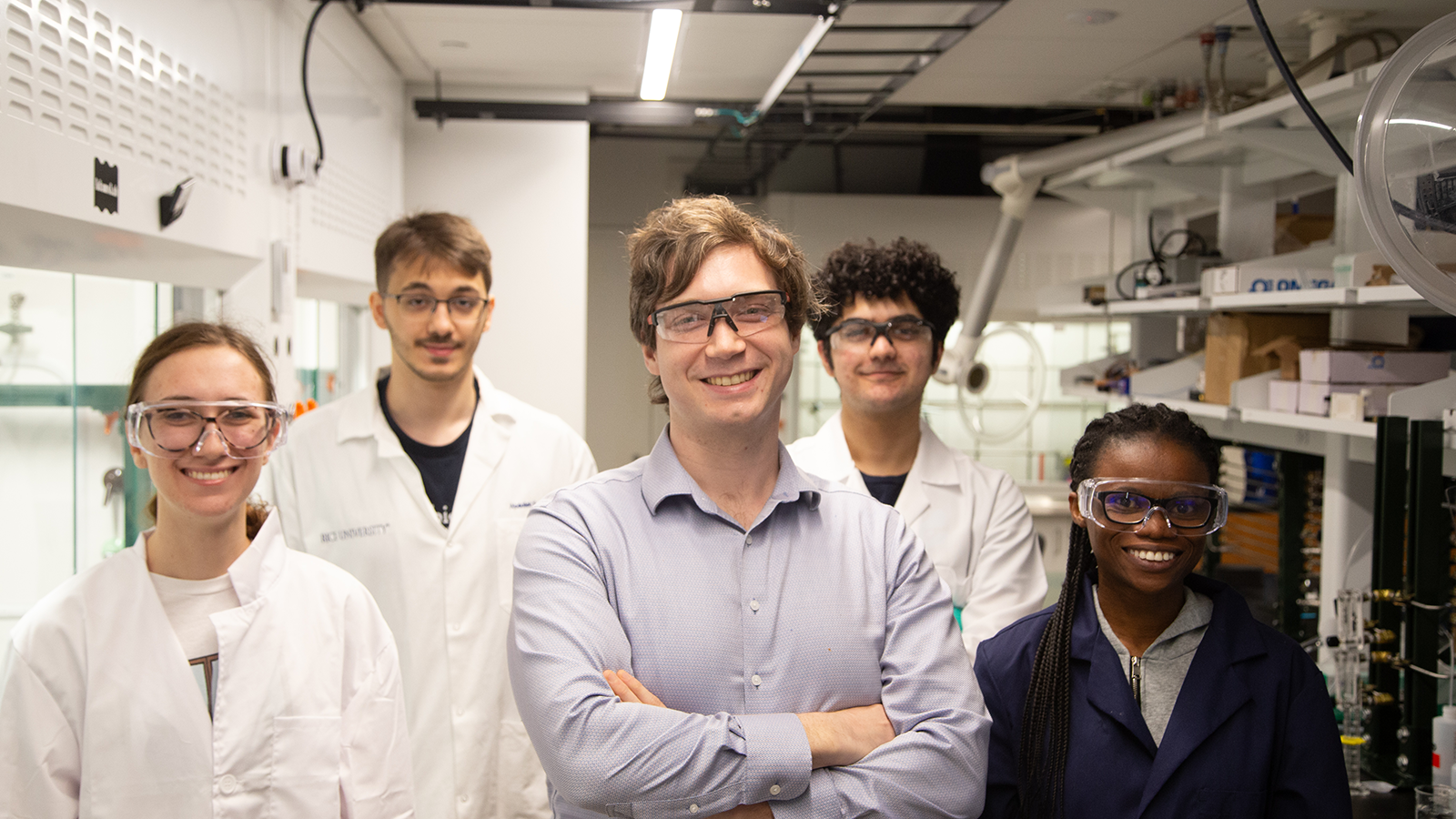

He also sees mentorship as central to the mission. “At the end of the day, my students are the ones carrying this work into the future. If I can help shape how they think about sustainability and innovation, that’s a legacy I’m proud of.”

As the world races to decarbonize critical sectors, researchers like Jason Adams are lighting the way—sometimes quite literally—by turning up the voltage and dialing down the heat.

About REINVENTS:

REINVENTS (Rice Engineering Initiative for Energy Transition and Sustainability) leverages Rice Engineering and Computing’s efforts in energy and sustainability and partners with industry to develop innovative solutions that address existing and emerging environmental and climate concerns. As a 1:1 accelerator for scalable energy solutions, REINVENTS develops transformative technologies for energy security and independence and supplies an energy talent pipeline for the workforce of the future.